- HIGH QUALITY GUARANTEE

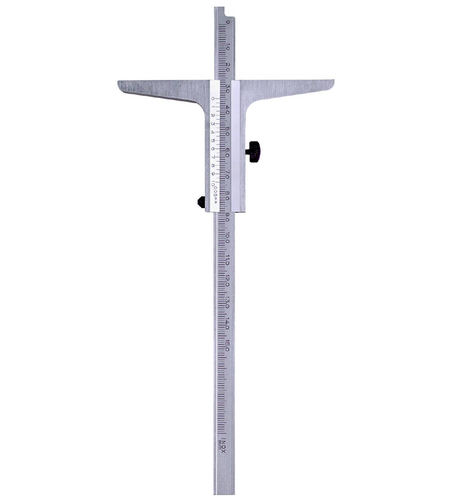

depth

gauge caliper

depth

Enables precise measurement of the depth of slots or holes. The unusual jaws, which are set at opposite ends of the measured hole during measurement, are also used to read the measurement.

gauge caliper

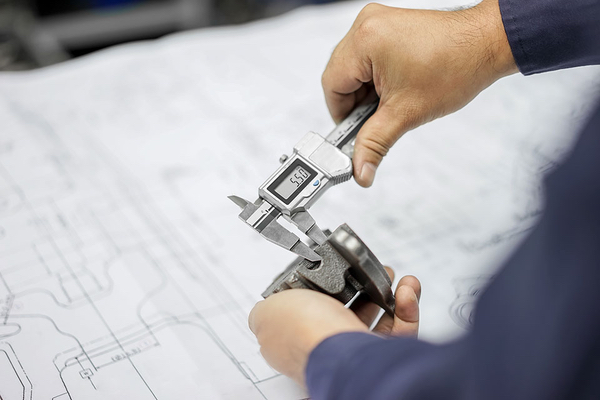

caliper

inside

caliper

Made of stainless steel with a vernier scale in mm with a measurement accuracy of 0.02 mm. With this caliper you can measure the inside diameter and back cut grooves. The caliper is independent of batteries and external devicesźródeł zasilania i odporna na wilgoć i zabrudzenia. Wyposażona jest w śrubę ustalającą i ma regulację momentu na spodzie.

inside

micrometer

internal

micrometer

Internal micrometer used to measure, for example, the internal diameter of holes or through elements. The measurement is made by placing pins on the jaws into the holepomiarowych, a następnie ustawienie ich za pomocą pokrętła. Gdy trzpienie dotkną ścian wewnętrznych otworu i nie będzie już możliwości dalszej regulacji ich ustawienia, można w prosty sposób odczytać wynik pomiaru.

internal

mikromer

zewnętrzny

mikromer

Mikrometr zewnętrzny służą do pomiaru wymiarów zewnętrznych (np. średnic). Podstawowy, ekonomiczny mikrometr Mitutoyo z grzechotką zapewniającą powtarzalne pomiary.

zewnętrzny

micromer

external

micromer

We use a dial gauge to measure internal dimensions, and above all, the diameter of holes. The measurements obtained using them are characterized by high precision with diameters ranging from 4 to 800 mm.

external

sensor

clockwork

sensor

The main use of dial gauges is to check any geometric irregularities in details. Thanks to these devices, we can control the circularity of elements, as well as their flatness and parallelism of planes.

clockwork

test

pin

test

Pin and thread gauges are used to verify internal threads. Used for precise measurement processes, they provide accurate and reliable results.

pin

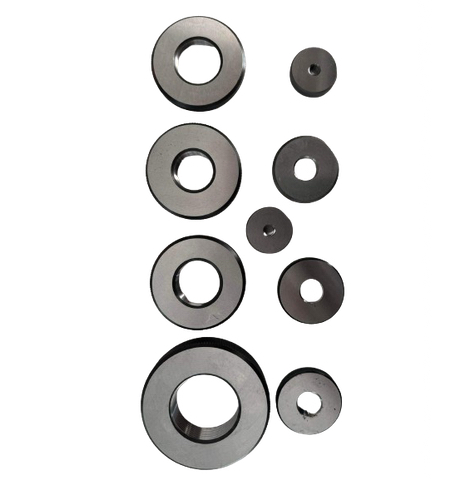

test

annular

test

Thread ring gauges are used to verify threads and consist of two or more rings, one of which has an internal thread and the other has an external thread.

annular